Ball Lollipop Forming Line

Batch Cooker :

Sugar, glucose & water has to be feed manually and cooked by a steam jacketed vessel which has an agitator to continuously stir the mass to avoid sticking to the walls, after which the cooked mass drops into the vacuum vessel.

Specification

Output : 500 kg/hr. Length : 1.27 m Width : 1.12 m Height : 2.15 m Weight : 660 kg Power : 1 HP AC

OR Continuous Cooker :

The product mass get cooked in stainless tell coil which goes to evaporation chamber & finally it reaches to vacuum vessel which is attached to vacuum pump.

Specification

Height : 2.15 m

Weight : 660 kg

Power : 1 HP AC

Vacuum Pump :

5 HP Water Ring Vacuum Pump

Motor-5 HP 1440 rpm (Crompton or Hindustan)

S.S Impeller

S.S Side Plate

Center Body S.S Sleeve

Water Jacketed Cooling Table :

The cooling plate consists of smooth polished steel plate with cold water circulating channel underneath which ensures uniform cooling. It can be supplied with edged rails which also serves as a guide rail for product mass.

Specification

Batch Size : 45 kg

Length : 6ft

Width : 3ft

Height : 2.5ft

Weight : 240 kg

Pulling Machine :

Motor-2 H.P M.S Harded Gear Teflon Coated Shaft

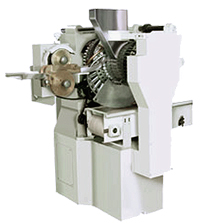

Batch Roller and Rope Sizer:

Batch Roller: Stainless steel trough is built up with stainless steel rotary conical roller which rotates clockwise & anti clockwise which converts the cooked mass into cone shape. Rope Sizer: Rope speed is infinitely adjustable to feed the forming machine. The speed of equalizing roller is so co-ordinated to ensure equal feeding to successive rollers.

Specification

Batch Size : 80 kg Length : 3.7 m Width : 0.72 m Height : 1.35 m Weight : 1110 kg Power : 1 HP Gear Motor + 3.5 HP AC Rope Speed-10-50 meter per Minute

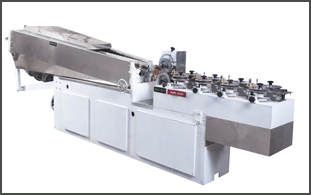

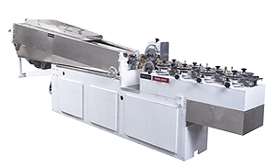

Ball Lollipop Forming Machine :

The size of the ball is infinitely adjustable. The continuous movement and long forming tracks leads to high form stability. The sticker feeder is accurately placed to avoid rejection. The speed of the machine is variable. Mini take off conveyor transports ball to the elevating conveyor.

Specification

Output : 1500 kg / Shift Length : 1.250 m Width : 1.10 m Height : 1.35 m Power : 2 HP DC

Deck Cooling Conveyor :

Specially designed for ball lollipop. Balls are taken by elevating conveyor. There are five overlapping trays oscillating by crank shaft. The rolling of lollipop prevents deformation. Refrigeration system is installed to cool the product

Specification

Output : 1500 kg / hr. Length : 2.4 m Width : 1.5 m Height : 2.1 m Power : 3 HP with AC